Thermal Bridging

With the increasing focus on energy conservation in the last few years, building codes have increased insulation levels, tightened air barrier requirements, and set lower levels of energy use for lighting and HVAC. And with these energy saving mandates come clarifications on construction techniques.

Let's look at the roof insulation for projects installing it entirely above the deck. The 2018 International Energy Conservation Code, Chapter 4 Commercial Energy Efficiency, requires that insulation be continuous, for one, and secondly, it "shall be installed in not less than two layers and the edge joints between each layer of insulation shall be staggered."

It has always been good roofing practice to install your roof insulation in two or more layers and to stagger joints of insulation boards.

Installing one thick layer of insulation allows for more thermal loss between the joints of the insulation from the roof deck level to the membrane level. This means that in the wintertime, heat is being transferred faster through the joints of the insulation than moving through the body of the insulation itself. If you anchor that one layer of insulation with a mechanical fastener and plate down to the steel deck, you add to the thermal conductivity or thermal bridging, allowing the heat to travel straight from the steel deck, along the fastener to the plate.

How much thermal loss are we talking about? The ASHRAE Handbook of Fundamentals has energy calculations in Chapter 23, and a 1/8” gap (which is a standard insulation and cover board gap seen in the field today) could result in an energy loss of up to 10%. If you have a less than ideal installation and have areas which have 1/4” gaps, you could see energy losses of up to 18%. Staggering two or more layers of insulation allows the slowing of thermal loss at the joints from one layer to another.

And when two or more layers are used in an assembly, the first layer can be fastened to the roof deck with fasteners and plates, and all the subsequent layers can be installed using insulation adhesive. This practice keeps those metal fasteners from becoming thermal bridges all the way through the roof assembly.

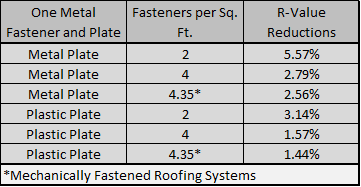

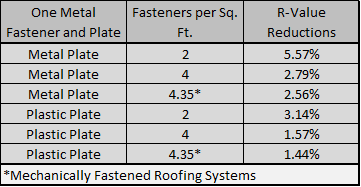

An analysis of heat transfer, or thermal bridging, in roof assemblies with fasteners and plates was conducted and published in Roofing Research and Standards Development STP 959. The results are below:

This was a was a needed change for the building code and energy efficiency in roofing. Even if it was just codifying good roofing practice, energy savings will be achieved using these methods.

For information regarding the minimum R-Values for roof insulation in your state, click here.

For more information on fasteners and plates, click here

Contact Craig Tyler at [email protected] with questions.

Let's look at the roof insulation for projects installing it entirely above the deck. The 2018 International Energy Conservation Code, Chapter 4 Commercial Energy Efficiency, requires that insulation be continuous, for one, and secondly, it "shall be installed in not less than two layers and the edge joints between each layer of insulation shall be staggered."

It has always been good roofing practice to install your roof insulation in two or more layers and to stagger joints of insulation boards.

Installing one thick layer of insulation allows for more thermal loss between the joints of the insulation from the roof deck level to the membrane level. This means that in the wintertime, heat is being transferred faster through the joints of the insulation than moving through the body of the insulation itself. If you anchor that one layer of insulation with a mechanical fastener and plate down to the steel deck, you add to the thermal conductivity or thermal bridging, allowing the heat to travel straight from the steel deck, along the fastener to the plate.

How much thermal loss are we talking about? The ASHRAE Handbook of Fundamentals has energy calculations in Chapter 23, and a 1/8” gap (which is a standard insulation and cover board gap seen in the field today) could result in an energy loss of up to 10%. If you have a less than ideal installation and have areas which have 1/4” gaps, you could see energy losses of up to 18%. Staggering two or more layers of insulation allows the slowing of thermal loss at the joints from one layer to another.

And when two or more layers are used in an assembly, the first layer can be fastened to the roof deck with fasteners and plates, and all the subsequent layers can be installed using insulation adhesive. This practice keeps those metal fasteners from becoming thermal bridges all the way through the roof assembly.

An analysis of heat transfer, or thermal bridging, in roof assemblies with fasteners and plates was conducted and published in Roofing Research and Standards Development STP 959. The results are below:

This was a was a needed change for the building code and energy efficiency in roofing. Even if it was just codifying good roofing practice, energy savings will be achieved using these methods.

For information regarding the minimum R-Values for roof insulation in your state, click here.

For more information on fasteners and plates, click here

Contact Craig Tyler at [email protected] with questions.

Up Next

November 18, 2020

Uplift Testing for Induction Welded Systems

What tests have been performed for induction welded systems, and how do the results compare to conventional mechanically fastened systems?

November 04, 2020

VOCs and Roof Membrane Bonding Adhesives

Volatile Organic Compounds (VOCs), along with Nitrous Oxide (NOx), are compounds which react with UV rays from the sun to produce ozone. Increased levels of ground-level ozone can affect overall air quality.

October 21, 2020

LEED, Green Globes, and Living Building Challenge

With all of the “going green” initiatives that are underway in every aspect of our lives, there are three main programs that are pushing buildings to be more sustainable: LEED, Green Globes, and Living Building Challenge (LBC).